Recently, my client asked me: He noticed that batteries from brands don’t have protection boards. That’s because some people on Reddit https://www.reddit.com/r/flashlight/comments/1m74xkp/question_about_using_an_unprotected_21700_cell_in/ said, “As long as the flashlight has built-in circuit protection, battery protection boards aren’t needed.”

I’m sorry to see such a view—many people are being misled by it.

Here is my opinion:

No, that’s not true. Battery protection boards are still essential, even if flashlights have built-in circuit protection. A dual-protection system (battery protection board + flashlight’s internal protection) is an industry safety standard, not redundant.

Why Is Dual Protection Necessary?

1. Differences in Protection Mechanisms

- Battery protection board: Directly monitors battery status, responds to short circuits in 0.1 seconds, and prevents overcharging, over-discharging, and overheating—it’s the battery’s “personal bodyguard.”

- Flashlight circuit protection: Primarily safeguards the LED and internal circuits, with slower response times and limited protection scope.

2. The Importance of Safety Redundancy

- A single protection layer carries high failure risks; dual protection provides a backup safety net.

- Battery protection boards can immediately cut off power if the battery accidentally shorts (e.g., contact with metal during carrying)—a scenario the flashlight’s internal protection can’t cover.

3. Industry Standard Requirements

- International safety certifications (UL1576, CE, etc.) mandate that lithium batteries must have overcharging/over-discharging/short-circuit protection, which is typically provided by battery protection boards.

Risks of Batteries Without Protection Boards

Unprotected batteries are serious safety hazards, potentially leading to:

- Fires if crushed or short-circuited during transportation (flashlights and batteries are disconnected, leaving batteries unprotected).

- Fire risks if batteries are removed, used in other devices, or accidentally dropped.

- Overheating, swelling, leakage, or even explosion; significantly shortened battery lifespan.

Why Do Some Brands Use Unprotected Batteries?

- Cost savings: Reduces costs by approximately $0.50 per battery.

- Performance considerations: Slightly lowers battery internal resistance and boosts maximum output current (but at the cost of increased safety risks).

Conclusion

We strongly recommend continuing to use batteries with protection boards, even if your flashlight has built-in protection. The dual-protection design offers comprehensive safety in key scenarios:

- During charging (flashlight protection may not cover this process).

- When the battery accidentally shorts (e.g., carried in a pocket with keys).

- If the flashlight’s internal protection fails (any electronic device can malfunction).

Safety should not come at the cost of a $0.50 savings—especially given the potential risks of lithium batteries.

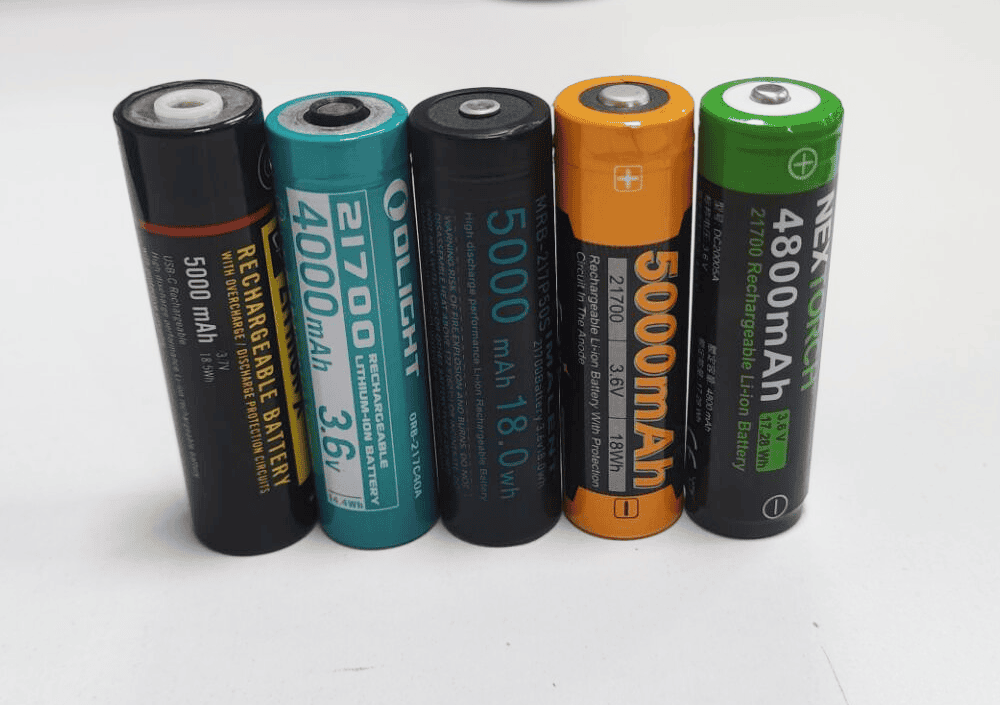

We’ve been making flashlights for 20 years, and all the batteries we supply with them come with protection boards. Of course, our flashlights also have built-in circuit protection—so that’s our double safety layer. In fact, nearly all major flashlight brands—such as Olight, Fenix, Ledlenser, Nextorch, Nitecore, and Coast—put both circuit protection and battery protection boards in their products. This way, they offer double protection.

How to Determine if a Battery Has a Protection Board

I. Visual Identification Method

1. Dimension Measurement

Batteries with a protection board are longer than those without. Fox example

- Unprotected 18650 battery: Length ≈ 65mm; Protected 18650 battery: Length ≈ 68-72mm (protection board adds 3-7mm in length)

- Unprotected 21700 battery: Length ≈ 70mm; Protected 21700 battery: Length increases by ~3-5mm, total length ≈ 73-75mm

2. Surface Feature Observation

- Protected batteries: May have slightly raised lines on the wrapper (traces of metal tabs connecting positive/negative terminals).

- Uneven wrapper: Wrapper around the protection board area may be uneven or bulging.

- Negative terminal feature: Protected batteries often have a small circular protrusion or welding marks on the negative terminal.

3. Label Check

- Protected batteries: Wrappers/labels may display “With Protection Board”, “带保护板” (Chinese), or similar markings.

- Model indication: Some brands mark models with “P” (e.g., 18650P, where “P” stands for Protected).

II. Functional Testing Method (Safety First!)

1. Short-Circuit Test (Dangerous! For small-capacity batteries only, operation time < 1 second)

- Protected: No obvious heating after short-circuiting positive/negative terminals; output stops quickly (<1 second).

- Unprotected: Rapid heating, possible smoking, or even fire (prolonged testing is strictly prohibited).

2. Over-Discharge Protection Test

Discharge to ~2.4V with a load:

- Protected: Automatically stops discharging when voltage drops to ~2.3-2.4V.

- Unprotected: Continues discharging to 0V, causing permanent battery damage.

III. Multimeter Testing Method (Recommended)

1. Voltage Measurement

- Fully charged lithium batteries: Normal voltage ≈ 3.7-4.2V.

- Protected: Measured voltage is normal and stable.

2. Internal Resistance Test (Professional)

Using a multimeter or professional internal resistance meter:

- Protected: Internal resistance typically 50-150mΩ.

- Unprotected: Internal resistance usually <50mΩ (not absolute, for reference only).

3. Protection Function Trigger Test (Exercise Caution)

- Discharge to ~2.0V:

- Protected: Multimeter shows voltage drops to 0V suddenly (protection board cuts off output).

- Charge to >4.3V (Dangerous! For discarded batteries only):

- Protected: Charging current drops to 0 suddenly (overcharge protection triggers).

IV. Disassembly Verification Method (For Discarded Batteries Only)

Carefully remove the battery wrapper:

- Protected: A small black PCB circuit board is visible, connected to the positive/negative terminals.

- Unprotected: Only the bare battery cell, no additional circuit components.

V. Special Judgment Method for Multi-Cell Battery Packs

- Multi-cell series packs with 3 or more wires (additional colored wires besides positive/negative): Usually have a protection board; extra wires are for the NTC temperature sensor.

Safety Warnings

- Overcharging/over-discharging unprotected batteries is strictly prohibited—it may easily cause fire or explosion.

- Short-circuit tests are only for small-capacity batteries, with operation time < 1 second.

- For those unfamiliar with operations, prioritize visual and label checks to avoid dangerous tests.

Summary

Genuine lithium batteries should always be equipped with protection boards, especially for high-power devices. Dual protection (device-built-in protection + battery protection board) is an industry safety standard, not redundant design.

3 Responses

Lodi291casino, not bad! The bonuses are pretty decent and they keep things interesting. Give it a shot, might surprise you. Don’t forget to claim your bonus lodi291casino.

Heard some buzz about pkr555. Anyone tried it out yet? Looks interesting! I’m gonna give it a whirl. Check it out pkr555

Alright, folks, looking for the lucky505download? Just grabbed it myself. Seems legit! Get yours here lucky505download