“Reliable quality” is a shared goal among all manufacturers—but how to prove that reliability? For us, the answer lies in IATF 16949 certification—a credential globally recognized by the automotive industry as a “Quality Passport.” It is not only our solemn commitment to quality but also the core competitive edge that sets us apart from ordinary manufacturers.

Today, let’s explore two key questions: Just how valuable is IATF 16949 certification? And as a flashlight manufacturer holding this certification, what irreplaceable advantages can we offer you?

1. IATF 16949 Certification: More Than a Certificate—it’s the “Gold Standard” for Automotive-Grade Quality

Many people know ISO 9001 as a general quality management system certification, but IATF 16949 is far more rigorous. Developed by the International Automotive Task Force (IATF), it is a specialized quality management standard exclusively for the global automotive industry, designed for the entire automotive supply chain (from components to finished vehicles). Its core focuses on “zero-defect orientation” and “maximizing customer satisfaction.” The value of this certification lies in three “extraordinary” aspects:

1.1 Extraordinary Positioning: A “Mandatory Entry Ticket” for the Automotive Supply Chain

IATF 16949 is not an “optional certification”—it is a mandatory requirement for suppliers by major automotive brands (such as Toyota, Volkswagen, and General Motors). Without this certification, even products of exceptional quality cannot enter the automotive supply chain.

What does this mean for us as a flashlight manufacturer? Earning this certification proves that our production, quality control, and management capabilities have reached the level required to “supply the automotive industry.” To put it in perspective: the automotive industry demands “zero-failure” performance from its components. For example, vehicle-mounted emergency flashlights must work stably under high temperatures, vibrations, and electromagnetic interference—any failure could compromise driving safety. A quality system that meets such strict standards far exceeds the industry norms for ordinary flashlights.

1.2 Extraordinary Standards: Beyond “Meeting Requirements”—Over-and-Above Control for Risk Prevention

At its core, IATF 16949 builds on ISO 9001 and adds a host of automotive-specific “enhanced requirements”, with a strong emphasis on “process control” and “risk prevention.” For instance, manufacturers must implement the five core tools:

- APQP (Advanced Product Quality Planning): Plan ahead during the flashlight design phase. For example, when developing vehicle-mounted flashlights, we consider scenarios like “-40°C low-temperature battery life” and “1-meter drop impact resistance” to avoid rework later.

- FMEA (Failure Mode and Effects Analysis): Identify potential risks in advance (e.g., “poor battery contact” or “insufficient switch lifespan”) and optimize targeted solutions (such as using gold-plated contacts or reinforcing switch structures).

- SPC (Statistical Process Control): Real-time monitor key parameters during production (e.g., the wall thickness of flashlight housings or brightness deviations) to ensure consistent quality across every batch.

- MSA (Measurement System Analysis): Ensure the accuracy of testing equipment (e.g., brightness meters, weather resistance test chambers) to avoid misjudging product qualification.

- PPAP (Production Part Approval Process): Before mass-producing new products, provide customers with complete verification reports (e.g., lifespan test data, environmental test results) and only start production after confirming requirements are met.

These requirements are not about “fixing problems after they occur”—they are about “preventing errors throughout the process.” While ordinary manufacturers may rely on “sampling inspections” to ensure quality, we use a systematic approach to guarantee that every single flashlight meets standards.

1.3 Extraordinary Certification Process: Every Step is a “Test of Strength” (From Application to Maintenance)

The IATF 16949 certification process is far more complex than that of ordinary systems:

- Preparatory Phase: Establish and operate the system for at least 3 months, and complete internal audits.

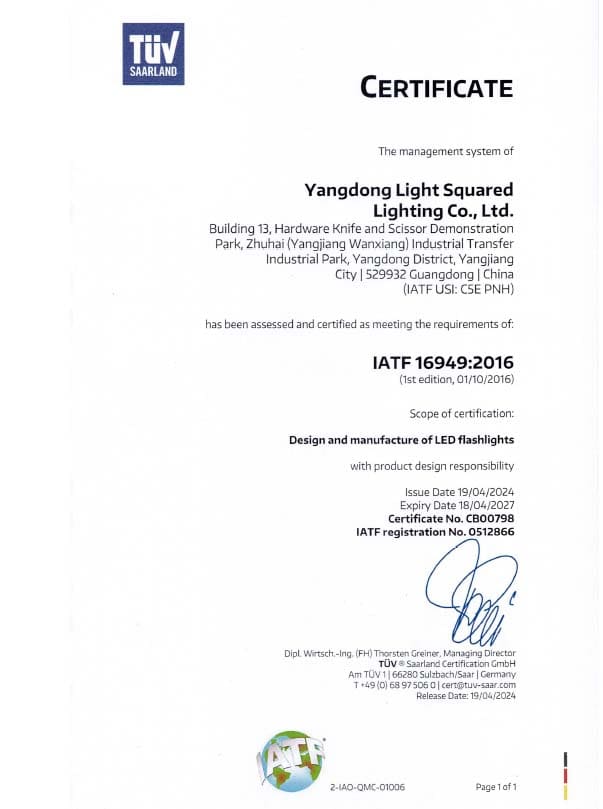

- External Audit: Authorized bodies (e.g., TÜV) conduct on-site audits lasting 2–3 days, inspecting every process from design, procurement, and production to after-sales service (e.g., verifying if FMEA reports are implemented or if SPC data is authentic).

- Continuous Supervision: After certification, annual “surveillance audits” are required, and a full “recertification audit” is needed every 3 years. If the system is found to be ineffective, certification is immediately suspended or revoked.

Statistics show that the first-time pass rate for IATF 16949 is less than 60%. This means manufacturers that obtain this certificate have undoubtedly undergone rigorous refinement—it is by no means a matter of “merely buying a certificate.”

2. What Can We Offer You as an IATF 16949-Certified Flashlight Manufacturer?

For our customers, choosing us means more than choosing a flashlight—it means choosing an automotive-grade quality assurance system. Specifically, you gain five core advantages:

2.1 Products: Automotive-Grade Reliability for More Demanding Scenarios

Ordinary flashlights may only meet basic “daily lighting” needs, but our products excel in extreme conditions:

- Vehicle-Mounted Emergency Flashlights: Passed -40°C to 50°C high-low temperature cycle tests, 50,000 switch lifespan tests, and 1.5-meter drop tests. They remain stable even under vehicle vibrations and electromagnetic interference.

- Flashlight Materials: Housings use automotive-grade aluminum alloy and ABS+PC materials, resistant to oil and corrosion. Brightness deviation is controlled within ±5% (compared to ±10% for ordinary products), meeting the needs of long-term continuous operation.

- Outdoor Adventure Flashlights: Battery life deviation is no more than 10% (ensured by SPC monitoring of cell consistency), and they have an IP67 waterproof rating (every batch undergoes random water immersion testing).

These are not “marketing gimmicks”—they are “standard practices” under the IATF 16949 system. Every performance metric is supported by data and strict processes.

2.2 Market Access: Directly Connect to the Automotive Supply Chain, Saving Extra Verification Costs

If you are an automotive manufacturer or auto parts supplier in need of supporting flashlights (e.g., for emergency toolkits or vehicle-mounted lighting), choosing us eliminates the need for additional “quality system audits.” Our IATF 16949 certification is recognized by major global automotive brands, directly meeting your supply chain entry requirements and saving you 3–6 months of verification time.

Even if you are not in the automotive industry (e.g., industrial or outdoor brands), this certification still saves you “trust costs.” You no longer need to repeatedly inspect our production processes or quality control standards—our certification serves as authoritative quality endorsement.

In Closing: Choosing IATF 16949 Certification Means Choosing “Certainty”

In the flashlight market, there are plenty of “low-cost” or “feature-packed” products—but few can withstand the test of “automotive-grade standards.” If you need:

- A flashlight that works stably in harsh environments (low temperatures, vibrations, frequent use);

- A partner that connects quickly to the automotive supply chain and eliminates extra audits;

- Quality assurance backed by an authoritative system, not just verbal promises;

Then choosing us—an IATF 16949-certified manufacturer—means choosing “quality certainty.”

Currently, our automotive-grade flashlights have been supplied to multiple auto parts manufacturers, and we provide customized solutions for industrial and outdoor clients.

If you have needs, please feel free to contact us—let’s create more reliable lighting products for you, up to automotive-grade standards.